Types of Laminated Glasses

Two panels of glass are combined to create laminated glass, which is then permanently joined by interlayers of either Ethylene Vinyl Acetate (EVA), Polyvinyl Butyral (PVB) or Sentry (SGP/bulletproof). Even when damaged, the interlayers maintain and hold the glass to provide a solid, even shield. Laminated glass can be produced in a variety of thicknesses and coatings to achieve a variety of properties, such as environmental benefits or improved soundproofing hence the reason why Laminated glass is also known as safety glass.

Exactly how might it be utilised?

Laminated glass is a perfect replacement for normal glass in a number of applications because it offers a very durable, transparent layer:

- For use in constructions where there is a substantial threat of hurricanes or other natural calamities

- For windows of businesses or residences at a greater risk of burglary

- Railing for balconies or walkways.

- At retail locations as display cases for jewels

- Enclosures for wildlife or aquariums

- Glass ceilings and floors

- Glass steps

- Overhead Glazing - Skylights or Canopies

- Excessive noise reduction - windows in houses or flats.

Specifications

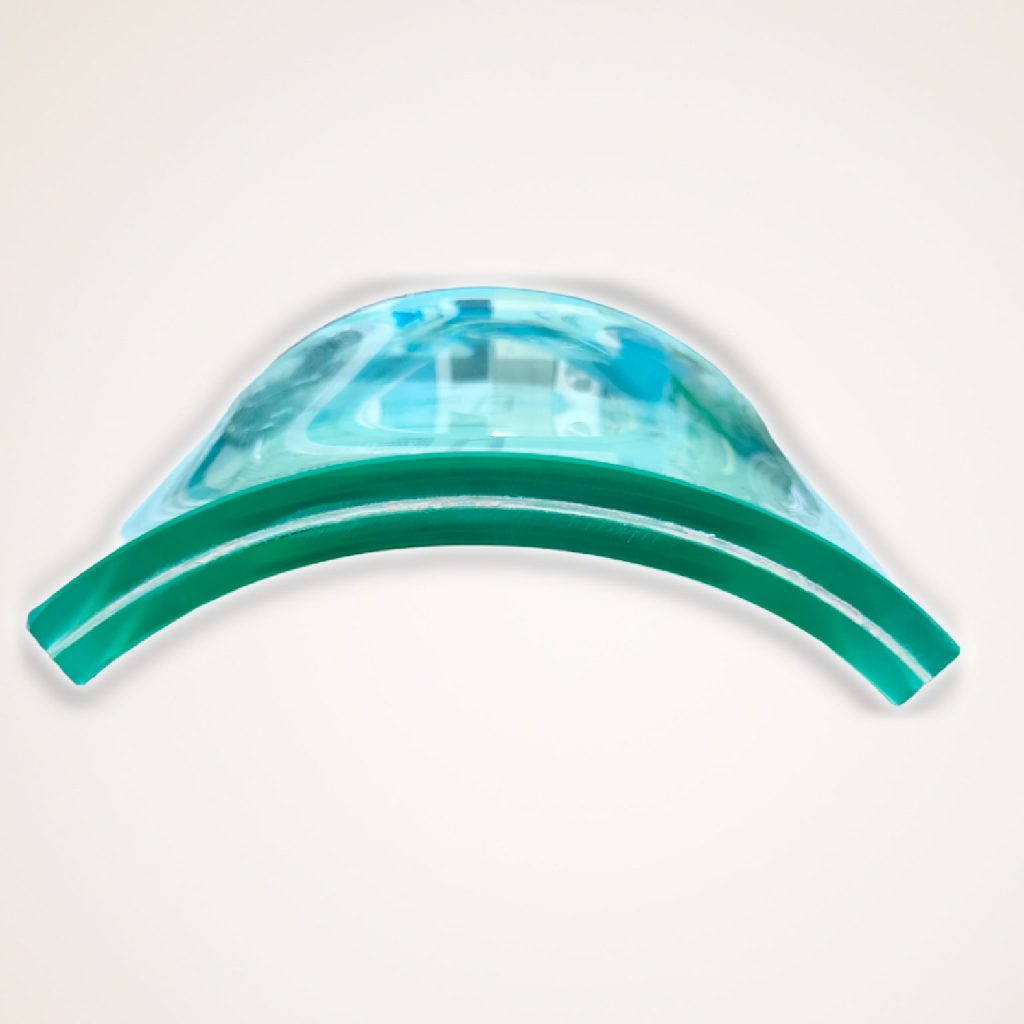

Please note: only cylindrical (C shaped) bend glasses can be laminated.

Glass Thickness

4mm – 19mm

Minimum Flat Glass thickness after lamination

6mm

Maximum Flat Glass thickness after lamination

50mm

Minimum Curved Glass thickness after lamination

9mm

Maximum Curved Glass thickness after lamination

50mm